Table of Contents

- What Is Die Casting and Why Does It Matter?

- The Role of a Die-Casting Consultant

- Key Benefits of Working With Industry Experts

- Real-World Challenges: Common Die Casting Issues

- How Consultants Solve Process and Quality Problems

- Case Studies: Tangible Impacts on Manufacturing

- Emerging Technologies and Die Casting

- Choosing the Right Die-Casting Consultant for Your Needs

What Is Die Casting and Why Does It Matter?

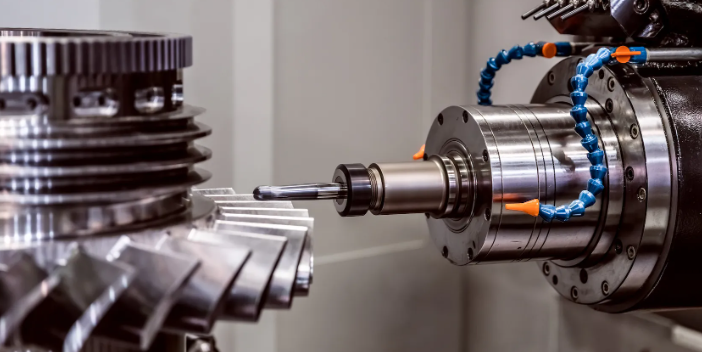

Die casting is a widely used and highly efficient manufacturing method where molten metal is injected under extreme pressure into steel molds called dies. This process allows for the mass production of intricate and precise metal parts that would be time-consuming or impossible to create by traditional machining. These parts are essential in various fields, especially industries where strength, consistent quality, and detailed shapes are critical, such as automotive, aerospace, consumer electronics, and industrial machinery. Die casting supports economic growth and innovation by delivering high-performance parts at scale and within tight manufacturing tolerances.

With so many applications and rapidly changing technology, die cast engineers work is more important than ever in connecting creative product designs with real-world production success. Advancements in both tooling design and process automation help keep this manufacturing method at the forefront of modern production strategies. According to recent die casting technology advancements, manufacturers are increasingly adopting improved alloy formulations, high-speed machines, and digitized process monitoring. By enabling a faster turnaround and more reliable outcomes, die casting remains vital to competitive manufacturing on a global scale.

The Role of a Die-Casting Consultant

A die-casting consultant brings specialized experience to help organizations optimize every aspect of their casting operations. Their work generally begins with an in-depth assessment of current processes, including reviewing designs, equipment settings, materials used, and historical production data. The consultant’s keen eye can identify inefficiencies that may be overlooked in day-to-day operations, such as suboptimal cycle times, unnecessary scrap, or excessive tooling wear. Managers and engineers benefit from the perspective of someone who has addressed various scenarios and challenges across the industry.

Consultants typically offer a broad range of services: conducting process audits, troubleshooting sticking points, evaluating tool life, recommending maintenance intervals, and providing actionable recommendations tailored to the shop’s unique needs. More importantly, these professionals collaborate with internal teams, guiding them through change management and skill-building, rather than simply offering theoretical advice. By staying involved through implementation, a consultant ensures that the recommended process yields measurable improvements rather than just sitting in a report.

Key Benefits of Working With Industry Experts

Partnering with a knowledgeable die casting expert can deliver several critical advantages for manufacturers striving to stay ahead in a margin-sensitive world. First, there’s the benefit of increased efficiency. A consultant can reexamine part designs and process variables—with fresh eyes—to discover new ways to cut cycle times, reduce machine stoppages, and eliminate bottlenecks. Over time, small improvements can add up to significant increases in throughput and lower per-part production costs.

- Cost Reduction: Streamlining operations with external expertise can lead to substantial cost savings, whether through optimizing raw material usage, recommending alternate alloys, or extending tool life.

- Quality Enhancements: By tightening process control, manufacturers can reduce the occurrence of defects, rework, and waste, resulting in consistently high-quality components that earn the trust of customers and end-users.

- Employee Development: Consultants don’t just fix problems; they empower internal teams to sustain and grow improvements, providing training and sharing best practices that last beyond their engagement.

Recent studies into manufacturing cost optimization strategies reveal that operations leveraging outside experts to refine manufacturing processes report an average operational cost reduction of 1% in the first year. This confirms that expert advice is not just for large enterprises. Even small or mid-size facilities stand to gain a competitive edge by engaging professionals who can unlock greater value within existing operations.

Real-World Challenges: Common Die Casting Issues

Despite careful planning, most die-casting operations encounter recurring challenges that impact performance and profitability. Porosity—tiny gas pockets or voids within the material—can weaken parts and complicate downstream finishing or machining. Incomplete fills result when molten metal fails to reach all areas of a mold, creating weak points or scrap material. Other frequent pain points include flash (excess metal on parting lines), cold shuts (where metal fronts do not fuse), and soldering (where the metal adheres to the die surface).

These process issues aren’t simply cosmetic—they have real costs. Flawed parts can extend project timelines, drive up inspection and labor costs, and delay customer deliveries. For manufacturers relying on just-in-time delivery or operating with thin inventories, frequent quality issues can disrupt production schedules and strain client relationships, underscoring the necessity for early diagnosis and permanent solutions.

How Consultants Solve Process and Quality Problems

To fix stubborn production problems, consultants employ a mix of rigorous analysis, modern technology, and shop-floor engagement. They might start by examining yield data to spot trends—like increasing scrap rates or deteriorating surface quality—then conduct hands-on evaluations of molds, machinery settings, and operator techniques. Consultants often introduce advanced diagnostics, such as thermal imaging, mold flow simulation, or metallurgical testing, to uncover subtle process flaws invisible to the naked eye.

- Root-Cause Discovery: Rather than treating symptoms, consultants zero in on why specific defects keep occurring, whether it’s an equipment calibration error, subpar mold design, or inconsistent raw materials.

- Team Collaboration: Solutions work best when everyone’s on board. Consultants build buy-in from line operators and engineers with hands-on demonstrations and clear instructions, making changes easy to follow and maintain.

- For long-term consultants, consultants pass on troubleshooting skills and best practices instead of one-off fixes so teams can proactively manage future challenges.

By fostering an environment of continuous learning and improvement, these experts help manufacturers build sustainable processes that can adapt to changing business needs and customer demands. This knowledge sets a quality consultant apart, producing benefits that last well beyond their direct involvement.

Case Studies: Tangible Impacts on Manufacturing

Many success stories highlight the value of enlisting a die-casting consultant. For example, one automotive supplier producing aluminum transmission housings experienced chronic porosity issues that resulted in high scrap rates and line stoppages. Once a consultant examined their tooling and process flow, a simple adjustment and speed—coupled with improved venting—drove down defective part rates by 40%. This saved substantial time and cost and improved morale on the shop floor.

In another real-world case, a consumer appliance manufacturer suffered delays caused by short shots—instances where the mold wasn’t quite filled. Their consultant used sophisticated flow modeling to suggest changes in gate locations and recommended a switch to a higher fluidity alloy. Within a month, the frequency of short shots dropped dramatically, lowering rework rates and getting finished products to market faster. These examples from high-volume and niche producers underscore how targeted expertise leads directly to measurable improvements.

Emerging Technologies and Die Casting

Innovation in the die casting firm. Adopting. Adopting data analytics, artificial intelligence, and empowerment enables manufacturers to reach new heights in efficiency and quality. Real-time monitoring with temperature, pressure, and shot-speed sensors helps catch deviations before they cause defects, while automation solutions control more variables and remove human error from repetitive tasks.

Consultants keep pace with this change, helping manufacturers assess which new technologies fit their needs, ensuring a smooth and cost-effective integration. Using digitized process control improves yield and provides deeper insights for ongoing optimization. As supply chains demand lighter, more complex, and environmentally friendly products, die-cast specialists are critical in advising how to leverage these capabilities without losing sight of reliability and cost-efficiency.

Choosing the Right Die-Casting Consultant for Your Needs

Selecting a qualified die-casting consultant requires careful consideration. Successful partnerships begin by identifying consultants with relevant technical expertise, specific industry, and familiarity with the alloys and machinery you use. Companies should also check references, looking for consultants who have driven measurable change before and shown the ability to work seamlessly with diverse teams.

- Review recent projects and results—a history of solving similar challenges often predicts a smoother engagement.

- Look for consultants who prioritize transparent communication and clear reactions, making it easy to act quickly on their findings.

- Assess their fluency with the state-of-the-art die casting technology and commitment to ongoing professional development.

- Establish clear project goals and milestones upfront, ensuring the engagement stays focused and productive.

Bringing in a die-casting consultant is an investment that extends far beyond a single project. With the right expertise and an open, collaborative approach, manufacturers can turn challenges into opportunities, drive efficiency, and build a culture of excellence that endures in a rapidly evolving manufacturing landscape.